Page 1 of 2

| Model railway signal box interior advice 09/12/2024 at 09:22 #159368 | |

|

Anothersignalman

107 posts |

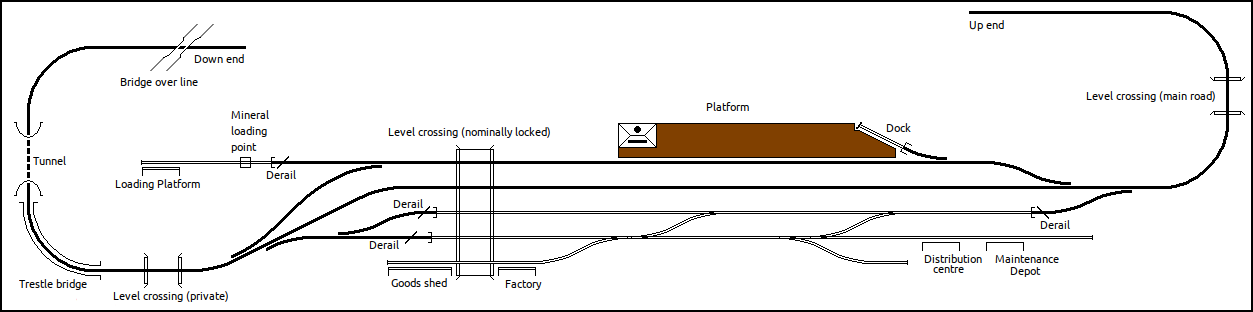

Hi all, Not sure if this is the right place to ask, feel free to move if necessary. My local model railway club has an HO/OO scale layout, representing about 70 miles of freelance mainline with ten or so stations (including branches). One of those stations is getting a new signal box structure, and I'm thinking about what sort of interior detail would be appropriate. The kit will be a Lineside West Highland Line signal box, Peco LK-202. Based on the number of windows on the front, I'm thinking a 20-24 lever frame would be appropriate, certainly no more than 25; does that sound right? Peco kit LK-202 The frame kit should probably be either a Peco/Ratio 553 20-lever frame, or a Springside Models DK1 or DK4 whitemetal kit. Peco 553 Springside Models DK1 Springside Models DK6 So, what colours should the levers be, and how many are required? I'm more familiar with the signalling practices of Victoria, Australia, and generally speaking we tended towards signalling every possible route from the lever frame directly, whereas the adjacent New South Wales Railways tended to only signal mainline moves, with ground frames (or sequences thereof) released by Annett Keys for access to/from the yard at various points. Which of those extremes are more likely, given the signal box architecture? It looks like a McKenzie style structure to me, which implies the 'signal every route' variant. The attached diagram is probably what we need to account for; some things are still a bit flexible. I'm not clear on whether the dock siding should be interlocked, or simply Annett or padlocked. The intermediate level crossing is semi-permanently padlocked with signs posted to that effect.  Post has attachments. Log in to view them. Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 10:00 #159369 | |

|

flabberdacks

640 posts |

NSW would put ground frames in for infrequently used points, or points too far from the box when another box wasn't justified. If you have access to ARHS Track & Signal diagrams, Thirroul box from 1967 is an excellent example. Can supply the diagram if interested. It's a decent size yard with frames at the far north and south ends, but the busy loco depot was right across from the box with all routes signalled up until shunters took over with hand points. So that makes me wonder what kinds of distances are imagined here. There could be some very heavy pulls in both directions, and likely the points on the hollow track in the sidings would be thrown by hand by a shunter or someone on the ground. That level crossing is also interesting, I would have thought the derails were better placed to the right of the crossing to better protect road/pedestrian traffic against a runaway off the sidings. Also are the points motorised or are there going to be FPLs for every facing move on the main line? That would increase the number of levers. Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 10:02 #159370 | |

|

bugsy

1789 posts |

I know that this is not relevant to your request, but would you be able to provide any photographs of your layout. I'm quite interested 🙂 Everything that you make will be useful - providing it's made of chocolate. Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 10:36 #159371 | |

|

kbarber

1746 posts |

May I just check: is the layout based on Australian practice? That might make quite a difference to the way a box was laid out. I suspect you're right to flag up which state it's set in as relevant as that, too, is likely to impact on how it would look. Lever colours In UK practice (and I suspect Australian practices were similar, though unlikely to be identical) lever colours depended on function. Standard UK colours (and some variants) were: Stop signals (including shunt signals): Red Distant signals: Yellow (green before the 1920s or thereabouts) Points: Black Facing point locks: Blue Spare: White Other locks/bolts (such as bridge bolts or releases for points worked from another box): Brown Ground frame releases: Blue over brown (The same would apply for Annett's Key release, with the key locked in the lever while Normal) Direction levers (for single lines), also interlocking levers for reversible working: Blue over brown Acceptance levers (for single lines): Red over brown Intermediate block signals: Red over yellow Detonator: Alternating black/white stripes; usually these were chevrons painted pointing up or down according to the direction of the line but some reversible lines had plain stripes. King levers (usualy for closing boxes, either on a single line or on Track Circuit Block lines): Alternating brown and white stripes * If a signal was released from another box (most often line clear release or token release) there would be a 3" white band half way down; for IB levers this usually separated the red and yellow sections. If a lever had become spare but had to be worked to maintain interlocking (such as an FPL lever rendered spare by motorising a set of points) the top half should be painted white and the lower half left in its former colour. The GWR painted Relief line signals red or yellow over black. For Goods lines the lever would have a 3" black band halfway up. There was at least one box on the former GN Main Line (Biggleswade) where IB levers were just red with a white band. However, the signals were effectively 'drivers' mas' (3-aspect colour lights at even intervals and indeed the down fast from Arlesey was worked by TCB) so the signal descriptions were somewhat nominal; I wonder if that was the reason. Sometimes the painters simply got it wrong. At Finchley Road (Midland) an outer home on the up goods had been abolished but the lever still had to be worked to get the distant signal. The lever was painted blue (though I recall it as a rather purple-tinted blue and very thickly painted, as if the paint had been put on with a palette knife!) Likewise at Kensington, where there were release levers on all lines for reversible working through the station, those in South Main were blue over brown while those in North Main were red. Lever layouts So far as setting levers out was concerned, in UK practice points/FPLs/etc tended to be clustered towards the middle of the frame, usually interspersed with shunting signals. Signals were at the ends of the frame and - so far as sensible - arranged so they could be pulled in a left-to-right or right-to-left sequence (then having to go back for the distant), including where there were junctions. An example of setting that out for a junction is visible for the up fast - up slow route at St Albans South https://signalbox.org/~SBdiagram.php/?id=%20150 shown as it was in 1970. (That was impossible to do, of course, on a 4-track layout where there were 'both-ways' crossovers.) On the North Eastern Railway, the 'pull-in-sequence' idea was taken further with home and starter wrong-way about so the signalman could pull all levers off without having to go back So the left hand end of a frame might look like: 1: Distant 2: Advanced starter 3: Starter 4: Home Great efforts were made to avoid 'pull-throughs' (where a lever had to be pulled between two others that were already reversed). However a frame was laid out when new, remodellings and alterations would lead to things being upset. Some boxes never changed at all during their lives. Others though... look at the up line sequences in that St Albans diagram again, a consequence of fitting in additional signals after St Albans North was abolished in the early 1960s. Number of levers This could be dramatically affected by the lever spacing, which varied very widely. The Midland Railway's 'tumbler' frame had levers at 6" centres, necessary to fit the mechanism in. Later, a 'tappet' variant was developed, again initially with 6" centres, but the REC/LMS/LMR developments of that reduced them to 4.5" centres. If I recall rightly the GWR's 5-bar vertical tappet frame had levers down to 4.25" centres, though I think older models (the 'double-twist' for example) were a bit wider. The Springside kit is definitely GWR (though I've never measured the lever centres accurately enough to tell what the spacing is). The Peco example looks like an uneasy amalgam of GWR and McKenzie & Holland (the latter particularly in the level crossing wheel). The LNWR used 6" centres, presumably because it was impossible to get levers any closer with the stirrup catch handle; their later habit of signalling everything and (usually) operating a crossover from 2 levers not 1 led to them having some very large boxes. Some companies left plenty of room at the ends of their frames. The GNR was a notable example; in their case it often meant new frames could be installed controlling extended layouts without having to build a new box. Others were more parsimonious. Some (the Midland and the LNWR for example) produced boxes and frames in standard sizes. The MR's were prefabricated at Derby and assembled like a big garden shed, using absolutely standard-sized 'flakes' delivered on a special wagon. The LNWR's weren't quite so rigid; they had a series of standard-sized panels that were put together in various combinations. LNWR frames were on 15-lever girders. MR frames were in 4-lever blocks. So it might be that sometimes a frame would be shoehorned in to a box that was really too short for it. Or sometimes it just couldn't be done, in which case (as at St Albans) the next size up had to be provided and there might be an excessive space at one end of the box. Conclusion I fear that's not a lot of help directly. As with most railway signalling (certainly the traditional kind) you pays your money and you takes your choice, and provided you have a good story for why things are as they are there is probably a prototype for everything. But hopefully those broad principles might help in thinking about how to do it. Log in to reply The following users said thank you: Anothersignalman, TUT |

| Model railway signal box interior advice 09/12/2024 at 10:43 #159372 | |

|

Andy174

95 posts |

In the UK if there's a signalbox present then all the routes including the dock siding that lead to the mainline would normally be controlled from there, the points that lead to the factories etc at the bottom could be just hand lever operated with the connecting line to them at just having controlled signals at either end to the main. Re lever colours they are basically: Distant signals yellow, stop signals including shunt ones red, points black & facing point locks blue, release lever for the crossing brown.

Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 12:36 #159373 | |

|

Anothersignalman

107 posts |

Thanks all, this has been really interesting so far. flabberdacks in post 159369 said: NSW would put ground frames in for infrequently used points, or points too far from the box when another box wasn't justified. The yard between arrival home signals is probably about 350-400 yards long. We have two main classes of "fast clock" timetables, one designed for operating at 6:1 accelerated time, and the other at 10:1, depending on how many people we have and the length of the operating session. For the 6:1 schedule, there are about sixty trains per day, including four pairs crossing, 15 through passenger and 19 through express (pass or goods) moves, and seven shunting trains (four goods, one railmotor shunt clear of the platform, one goods form mixed, one mixed form goods). For the 10:1 schedule, there are about thirty trains per day, including three crosses (two normal, one requiring a shunt-and-redock move); shunting is limited to three goods and one mixed train each way. So the up and down end points to/from 3 and 4 roads get used perhaps ten times per day, depending on what specific shunting requirements apply. Is that above or below the 'infrequently used' threshold? The dock is maybe twice a day, and the siding down end of the platform road might be three or four times per day as an upper limit; sometimes it doesn't get used at all. flabberdacks in post 159369 said: So that makes me wonder what kinds of distances are imagined here. There could be some very heavy pulls in both directions, and likely the points on the hollow track in the sidings would be thrown by hand by a shunter or someone on the ground. The station is a flat section with steep grades either side. Allowing for time and distance compression, I'd guess these grades equate to five miles uphill in the down direction (over trestle, through tunnel and under bridge), and downhill in the up direction (via public level crossing), each of about 1:40. If it helps, the load limit for a 5MT is about six 60ft bogie coaches, or maybe fifty axles' worth of goods wagons. flabberdacks in post 159369 said: That level crossing is also interesting, I would have thought the derails were better placed to the right of the crossing to better protect road/pedestrian traffic against a runaway off the sidings. The level crossing in the middle of the yard is semi-permanently locked against public use, to the point that the road surface has degraded significantly. This was my inspiration: https://www.westonlangford.com/images/photo/118931/ Between the crossing alignment and where the derails would go, there's probably space for at least three or four wagons on each of No.3 and No.4 roads. flabberdacks in post 159369 said: Also are the points motorised or are there going to be FPLs for every facing move on the main line? That would increase the number of levers. When were motorised points introduced at Scottish mainline crossing stations (featuring about thirty to sixty trains per day)? kbarber in post 159371 said: May I just check: is the layout based on Australian practice? My knowledge is mostly Australian, but the signal box structure we'll have to work with is explicitly Scottish, West Highland Line, so I need to adapt my thinking to match. Re lever colours, we used red for all signals or similar functions (e.g. shunt, accept, etc), black for all points, blue for all locks, white for spares, black-over-white for control (King, closing, pilot) and mechanical cross-lock (Annett's) levers, and blue-over-black for crosslock releases. Gate gear was always black. We didn't have yellow levers, but we did have a handful of green levers to control overhead power supply switching; and red/black alternating for non-railway signals e.g. tram signals intersecting with level crossings. I don't think we ever used brown (like the UK) or purple (Brazil?); nor did we have detonator levers. For the brown levers specifically, which paint colour/s would you recommend? I tend to use Humbrol red gloss 19, white gloss 22, blue gloss 48, black gloss 21. Same question for the yellow distant levers, though I'm guessing gloss 69 would be OK? kbarber in post 159371 said: Lever layouts Victoria had a few different interlocking engineers over the decades with their own preferences, but generally speaking we'd have either all functions in geographic order left or right, or more commonly, arranged with all mainline up signals at one end of the frame, all mainline down signals at the other end of the frame, to minimise walking and pull-betweens. I'd guess that the former arrangement might have been more closely tied to rocker frames than tappets, because the older style might have needed to minimise the number and lengths of shafts in use - but I don't actually know if that's true or not. We also had a mix of out-both-ways and in-both-ways lockbars, so there were quite a few instances where locks had to be put reverse, then throw the point, restore the lock, then pull the signal. Given that the structure is probably a McKenzie-style, tappet-era frame, that would point towards the mainline-up, shunt/yard, mainline-down arrangement of levers? kbarber in post 159371 said: Number of levers Does the Peco signal box generally match the Peco lever frame kit? We won't be using the gate wheel parts anyway. Are there other brands of OO scale lever frame kits you might recommend in lieu? kbarber in post 159371 said: Some companies left plenty of room at the ends of their frames. The GNR was a notable example; in their case it often meant new frames could be installed controlling extended layouts without having to build a new box. Others were more parsimonious. I've done a sample statistical analysis which showed a correlation of 92% between number of six-pane windows and number of levers, but it's far from complete. Generally speaking, we can take the number of six-pane windows on the front of the box, subtract two panes (one either side), then multiply by five for the total levers. So a box with 7x6-panes would be (7-2)*5 = 25 levers, +/-5. Our rocker frames could be any size, but tappet frames were almost always multiples of five, plus gate wheels, minus mule plates if applicable. If that logic holds true, then the Peco box would have room for a maximum of 25 levers; and I'm not certain that's enough to work this sort of track layout, at least without considering mechanical selectors on the shunt signals. Was that a common practice in the UK? We had plenty of cases of two discs worked by a single lever, but home-or-disc combinations were mostly gone by the early 1900s, and cases of home-or-calling signals from a single lever were always controlled by track circuits. kbarber in post 159371 said: Some (the Midland and the LNWR for example) produced boxes and frames in standard sizes. The MR's were prefabricated at Derby and assembled like a big garden shed, using absolutely standard-sized 'flakes' delivered on a special wagon. Off-topic, but that sounds really cool. Do you have any photos? Andy174 in post 159372 said: In the UK if there's a signalbox present then all the routes including the dock siding that lead to the mainline would normally be controlled from there Would the dock siding be signalled directly, or worked via Annett's Key? Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 13:25 #159374 | |

|

flabberdacks

640 posts |

Further to that, would normal working here involve shunting out onto the single line to get from one road to another? That would probably necessitate what NSW would call a starting signal. Something a reasonable distance down the single line that can be held at stop to control shunting movements but cleared to authorise a train to depart the area towards the next interlocking.

Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 14:00 #159375 | |

|

bill_gensheet

1427 posts |

You might find the Oban line website interesting as it contains fairly detailed, if Caledonian, layouts and boxes. Callander, Balquhidder, Killin Jn and Connel are the most relevant to you being the most complex through stations and generally better signalled. Oban line website There are also lots of diagrams on signalbox.org Should cover your queries about lever orders etc A single bidirectional platform is quite unusual though, but 'preferred' vs 'crossing' arrangements still exist - eg at Dunkeld and Dalwhinnie (HR) while WHL stations were mostly island platforms. These would be single box setups as bidirectional was never popular with the regulators. Your service levels are at the upper end of that seen on Scottish single lines, except maybe wartime north of Perth. Anothersignalman in post 159373 said:

UK had rules about distances from lever to points, which did slowly increase. This resulted in longer loops needing two lever frames, although not necessarily staffed as full signal boxes. See 'Nairn signallers bicycle', which had block instruments in the station building, and he cycled to each loop end box / encased frame. CR C&O tended to treat the loop as a bit of double track (see Balquhidder E & W), which makes you wonder if a single signaller had to call attention to himself. The current Dunkeld replaced two boxes when the north points were motorised. https://signalbox.org/~SBdiagram.php/?id=%20631 Any siding onto a passenger line had to be signalled and locked, but the extent of in-yard signalling varied. So on the 'newer' Balquhidder and Callander layouts there was a lot more signalling than say the 'original' Callander. A case of adding convenience over meeting legal minimums. As an extreme, Killin station only ever had one signal - which was from the siding ! Anothersignalman in post 159373 said: Very few ever did, as many did not have mains power. Some still do not have motor points - eg Stanley. Dunkeld now does - note the shorter levers Crianlarich Upper was fully mechanical up to closure in 1985 An early exception was Killin Junction, reconfigured in 1935 to one box and a fairly big ground frame where the cost of the motor point and adding track circuits was justified by saving on staffing somewhere half way up a mountain. Anothersignalman in post 159373 said:

[/quote] Direct locked and signalled. The '1935 modernised' Killin Jn layout on Oban-Line shows electric locks on some of the lever frame functions. Balquhidder West shows a dock siding exactly as your layout. Log in to reply The following users said thank you: Anothersignalman, TUT |

| Model railway signal box interior advice 09/12/2024 at 14:03 #159376 | |

|

Anothersignalman

107 posts |

flabberdacks in post 159374 said:Further to that, would normal working here involve shunting out onto the single line to get from one road to another? That would probably necessitate what NSW would call a starting signal. Something a reasonable distance down the single line that can be held at stop to control shunting movements but cleared to authorise a train to depart the area towards the next interlocking. It depends on how you define station limits and shunting on the single line. The way the yard is presently built, there's a single set of push-button controls at either end for "out, stop, in" and "in, stop, out" with the station between them. The Up Arrival signal (treated as an Absolute, but dressed like a Permissive; applies to all roads) is placed about where the word "Down" is on the main diagram, and the Down Arrival signal (dressed as an Absolute with a single Stop/Proceed indication, no shunt or route indications, applies to all roads) is placed halfway between the words "Up end" and the rightmost level crossing. There are a set of Up departure signals at the right end of 1, 2 (lopsided bracket) and 3 (dwarf) roads, and a down departure signal between the trestle bridge and tunnel portal. By those definitions, all shunting can be done inside the Yard Limits of the Arrival signals. Proper signalling is on my to-do list, but it could be years away. But the current project is to consider how the machine in the scale signal box might look, rather than reflecting the existing infrastructure. Shunting between 1 and 3/4 roads at either end, or between 3 and 4 roads at the down end, does require use of the mainline. I think the answer there would be to put the Arrival Home signals as close as possible to the first turnouts from each end with Limit of Shunt boards provided further out, protected by Outer Home signals or, if those don't exist, the bell code 'Release Tablet or Staff for Shunting' or whatever the Scottish equivalent would be? Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 14:37 #159377 | |

|

clive

2793 posts |

I thought I'd have a go at this, just for fun. At the Up end you've got three turnouts, all of which need a FPL. At the Down end there's two turnouts and a crossover; the crossover and one turnout need FPLs. I agree that the two turnouts and two crossovers in the yard would be hand-worked. So that's 11 levers unless you use economisers or motorized points, in which case you need 6. Signals is a lot harder. In the down direction we'd need a distant, a home at the level crossing (unless there's a gateman there), then two arms and two discs for the inner home, or two+one and a separate disc to allow shunting into the dock. Starters on the platform, through road (before the level crossing), and each line from the shed. A section signal on the trestle bridge. Plus we need some way to signal into the mineral line and perhaps an advanced starter on the through line beyond the level crossing. That's, um, 13 or 14 down signals. In the up direction it's a bit simpler: distant, home with two arms and two discs just before the level crossing, platform, through, and yard starters and discs to get out of the mineral line and dock. Then section signal at the level crossing. That's 11. Total 35 or 36 levers. Experts, how did I do? Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 14:47 #159378 | |

|

Anothersignalman

107 posts |

I've attached a rotated diagram (for the perspective of the 'signalman' rather than the actual model train operators) that I think is more or less to scale, showing how the station might have been interlocked if it abided by Victorian Railways principles, within the constraints of a 24 lever rocker frame and assuming switchlock mechanisms in lieu of separate point and lock levers were available at each end, along with track circuits for detection/selection of the Home and Calling-on signals. Without those functions it would need quite a bit more than 24 levers, and certainly a wider signal box. (Also, I'm not nearly crazy enough to try building a signal gantry with working discs.)

Post has attachments. Log in to view them. Last edited: 09/12/2024 at 15:12 by Anothersignalman Reason: None given Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 15:03 #159379 | |

|

clive

2793 posts |

kbarber in post 159371 said:I read somewhere that there's an alternative - less common but still found - where the signal levers are all put in the middle and the points etc. at the ends. If most moves are just straight through or just one or two lever pulls, there's much less walking around required. I've just found an interesting layout at Leamside (https://signalbox.org/~SBdiagram.php/?id=%201519). There's 55 levers, of which 35 are spares. The through moves, with no points movements, are 3,4,2, on the Up and 53, 52, 51, 55 on the Down. But if a train is reversing Up to Down, the move out of the Up platform is points 10, 8 and then signals 16, 51, which will be a long walk! Kirkby Jn (https://signalbox.org/~SBdiagram.php/?id=%201511) is another interesting one: 1-4 Up running signals, 6-8 Down running signals, 10-16 (goods) branch shunt signals and points, 17-20 trailing crossover signals and points. For each of the latter two groups, the objects operated by the levers are assigned in physical order of the object from left to right as the signaller faces the frame, rather than separating out signals and points. Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 15:15 #159380 | |

|

Anothersignalman

107 posts |

clive in post 159379 said:I've just found an interesting layout at Leamside (https://signalbox.org/~SBdiagram.php/?id=%201519). There's 55 levers, of which 35 are spares. The through moves, with no points movements, are 3,4,2, on the Up and 53, 52, 51, 55 on the Down. But if a train is reversing Up to Down, the move out of the Up platform is points 10, 8 and then signals 16, 51, which will be a long walk! Locally, we'd most likely have 51 as an automatic permissive signal with a note on the pull chart to the effect of, "51 need only be put normal when 5 or 6 is required". Was that an option in the UK? Note the bottom-left of the pull chart here: https://vicsig.net/photo/12912 Last edited: 09/12/2024 at 15:15 by Anothersignalman Reason: coding Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 15:50 #159381 | |

|

Anothersignalman

107 posts |

bill_gensheet in post 159375 said:Your service levels are at the upper end of that seen on Scottish single lines, except maybe wartime north of Perth.Good to know. This, combined with the diagrams you referenced through the rest of your post, seems to indicate that any such station would have long-since earned a larger lever frame than 20-25 levers, and therefore the proposed building probably isn't suitable? Maybe I should ask if we can kitbash two kits together; 12x windows across the front should allow for up to 50 levers. bill_gensheet in post 159375 said: A single bidirectional platform is quite unusual though, but 'preferred' vs 'crossing' arrangements still exist - eg at Dunkeld and Dalwhinnie (HR) while WHL stations were mostly island platforms.We're sticking with a single side platform due to the local terrain, though I could imagine that if a suburban electric service ever came through (and the yard was still necessary), the dock platform may well be extended around the back with a shotcrete retaining wall. bill_gensheet in post 159375 said: These would be single box setups as bidirectional was never popular with the regulators.Rather than two boxes with control levers between them, because of the risks of miscommunication and/or costs associated with the more complex locking? bill_gensheet in post 159375 said: Anothersignalman in post 159373 said:Off the top of my head, the local limit was about 400 yards for signal pulls, but less for points. We did start motorising Distant signals around the 1930s from memory. When we extended loops, we'd add one or two Double Wire levers bolted on to the end of an otherwise normal Rocker or Tappet frame. And at Moe station on the Gippsland line, we had a signal box with a frankenstein's monster of a machine with levers 1-4 double wire; 6-14 and 17 B Pattern direct tappet; 5, 15 and 16 A Pattern cam and tappet, plus an auxiliary 30 lever A Pattern frame.The yard between arrival home signals is probably about 350-400 yards long.UK had rules about distances from lever to points, which did slowly increase. This resulted in longer loops needing two lever frames, although not necessarily staffed as full signal boxes. bill_gensheet in post 159375 said: You might find the Oban line website interesting as it contains fairly detailed, if Caledonian, layouts and boxes. Callander, Balquhidder, Killin Jn and Connel are the most relevant to you being the most complex through stations and generally better signalled. Would any of these have had similar traffic numbers, 30-60 trains per day? bill_gensheet in post 159375 said: Any siding onto a passenger line had to be signalled and locked, but the extent of in-yard signalling varied. The dock platform isn't for passenger trains (or railmotors with passengers in them), it's for storage of a spare passenger carriage that could be used for the Mixed or to boost a train for holiday traffic, or to unload horseboxes. bill_gensheet in post 159375 said: Anothersignalman in post 159373 said:Ah, that's OK then, this place is outer suburban borderline rural but should have a permanent power supply, especially since the signals are all lights (to avoid maintenance issues with mechanical signals getting damaged by fat fingers).When were motorised points introduced at Scottish mainline crossing stations (featuring about thirty to sixty trains per day)?Very few ever did, as many did not have mains power. Some still do not have motor points - eg Stanley. bill_gensheet in post 159375 said: Anothersignalman in post 159373 said:Were plunger locks a thing in the UK?Direct locked and signalled. Last edited: 09/12/2024 at 15:51 by Anothersignalman Reason: None given Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 16:30 #159382 | |

|

bill_gensheet

1427 posts |

Anothersignalman in post 159381 said:The signal is to prevent whatever is in the siding from getting onto the main line, not for passenger movements. Remember the rules applied to these layouts were designed with horse/human powered shunting in mind. Killin https://www.flickr.com/photos/irishswissernie/45351012952 'Dwarf' signal from the yard only. On the 'main line' the train has the OTW staff for permission to move. Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 17:35 #159383 | |

|

bill_gensheet

1427 posts |

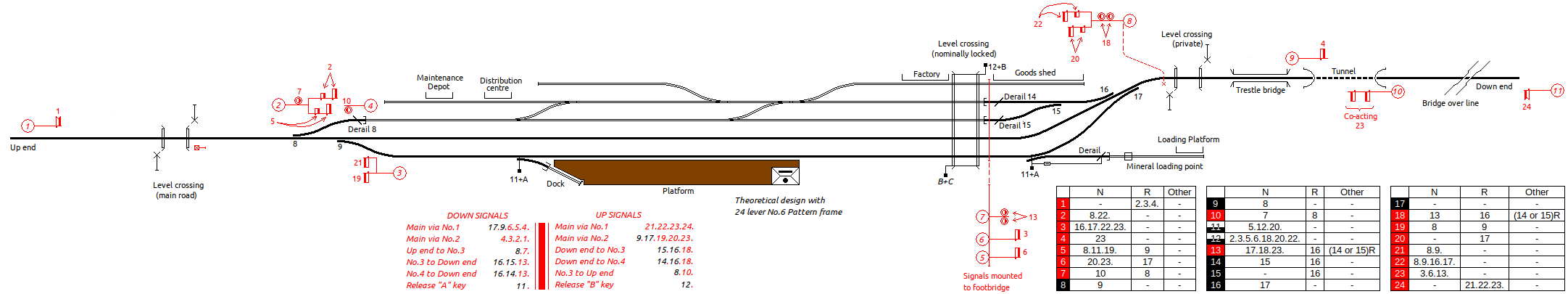

Anothersignalman in post 159381 said:bill_gensheet in post 159375 said:Below an absolute minimum setup which does keep to 24 levers, graphics from copying bits from the oban-line site.Your service levels are at the upper end of that seen on Scottish single lines, except maybe wartime north of Perth. It has fixed distants, not well suited to a main line with non-stop trains, and has the mineral siding worked by ground frame with electric lock. (ideas from Killin Jn). The shunt discs each end have a route display worked off the point lie (as Oban). 1 spare  Post has attachments. Log in to view them. Log in to reply The following users said thank you: TUT, Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 18:58 #159384 | |

|

Steamer

3989 posts |

Anothersignalman in post 159381 said:It's your layout so of course you can do as you please, but in reality if space were an issue (as it is at a couple of WHL stations that spring to mind), it would be a single platform with an island, potentially accessed solely by a barrow crossing. That kept the costs and land-take down, while keeping flexibility for passing trains and avoiding the need to bi-directionally signal the loop lines. Indeed, sidings at most passing loops on the remote Scottish lines are arranged to avoid the need for FPLs, in some cases meaning right-hand running applies through the loop. Anothersignalman in post 159381 said: Very doubtful- the Oban line currently has 6 passenger trains a day each way, and one shorter Oban- Dalmally trip. The other lines (Mallaig, Kyle of Lochalsh and Wick) have 4. From what I've gathered elsewhere the passenger service has never been busier than that, with the possible exception of excursion traffic to Oban. While there was freight traffic in the past, and some additional branches on some lines, 30 trains a day would very much be at the top end of the range. Again, your layout and do as you please to have fun with it, but it's probably best not to get to hung up on the operational side of it as it isn't really analogous to a real location. Anothersignalman in post 159381 said: bill_gensheet in post 159375 said:The GWR (and possibly others) went down that route, where the electric lock was released by pressing a plunger before moving the lever. On other frames, the lever catch was pulled and the lever moved a very short way (less then the depth of the lever), the lock released itself, and you then nudged it slightly back the way it had come before pulling it fully over. For power operated points, after doing the nudge routine, the lever is pulled 2/3 of the way over, until the points are detected in their new position, at which point it can be brought fully over.Anothersignalman in post 159373 said:Were plunger locks a thing in the UK?Direct locked and signalled. bill_gensheet in post 159375 said: Very few ever did, as many did not have mains power. Some still do not have motor points - eg Stanley.In the early days of motorisation some boxes had hand-operated generators which the signalman used to operate the points. The definitive example being at Challow as related by Adrian Vaughan in his autobiographies; that installation probably having gone in before the widespread installation of power lines outside the large towns (Challow is between Didcot and Swindon; rural yes but hardly remote) "Don't stress/ relax/ let life roll off your backs./ Except for death and paying taxes/ everything in life.../ is only for now." (Avenue Q) Log in to reply The following users said thank you: TUT, Anothersignalman |

| Model railway signal box interior advice 09/12/2024 at 20:41 #159385 | |

|

Anothersignalman

107 posts |

bill_gensheet in post 159383 said:Below an absolute minimum setup which does keep to 24 levers, graphics from copying bits from the oban-line site.I hadn't considered using a ground frame, that's a good idea. And there could even be a second one to work the dock platform, so that the full length of the platform road remains available. Peco kit SS91 contains parts for 2x four lever and 2x two-lever ground frames; they can probably be kitbashed to make a five-lever machine, but four should be fine: up and down signals, point, and lock lever. The latter would be released from the main frame, and when reversed, capture the key as well as unlocking the points. Then, with points reversed, either the up or down shunt signal could be worked. I note that you've shown the down end points sequence as signal-point-lock-point-lock; that's opposite to how I'd have expected it, because with out-both-ways lockbars that means you need to pull the points, then the lock on the right, then the signal on the left instead of running right-to-left directly. I gather that local practice was far more strict (after c.1910) about placement of shunting signals than in the UK, so we'd have to provide two signals from the derails down end 3 and 4 roads. As an example, this locking sketch from 1902 shows shunting ground disc 4 - https://drive.google.com/file/d/1Yfuxvk7AETALPze-OmpBmU0ixmtd9bKO/view - between home signals 2,3 and mainline roads 1 and 2. I think that sort of mid-section shunt signal was common for UK practice, but that signal was likely removed circa November 1912. So, is it acceptable in UK practice to have a single combined shunt signal further along like that, or is it that the turnout 3/4 roads becomes a hand-throw, which is why you added the catch? We don't have room for a catch or derail in that position, but we could probably interlace catches with the hand-throw turnout. I think the 24th lever needs to be a signal, you've shown 12 red levers for 8 homes and five dwarfs. Unless the dwarfs from dock and up end 3 road can be worked from one lever? Could the distant signals in each direction be automated, working based on slots from the relevant home signals similarly to how a home-over-distant on a single post would have been locked? Last edited: 09/12/2024 at 20:47 by Anothersignalman Reason: None given Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 20:49 #159386 | |

|

Anothersignalman

107 posts |

bill_gensheet in post 159382 said:Anothersignalman in post 159381 said:Good point, I hadn't considered that.The signal is to prevent whatever is in the siding from getting onto the main line, not for passenger movements. Remember the rules applied to these layouts were designed with horse/human powered shunting in mind. Log in to reply |

| Model railway signal box interior advice 09/12/2024 at 21:18 #159387 | |

|

TUT

535 posts |

What a splendid discussion you've got going here, although I'm still a bit unsure whether you're going for an Australian layout, a Scottish layout, or are you just generally interested in either or both? I notice for example you use the term derails and the symbol does look more like that of a derailer. To me a derailer is a device that goes on a rail and, uh, derails a train. They are not really that common in the UK I would say, we would tend to use trap points (which the GWR tended to call 'catch points', although a common convention is that 'catch points' are the ones you use to catch runaways down a gradient and 'trap points' are for trapping trains in sidings, providing flank protection, etc.) kbarber in post 159371 said: Intermediate block signals: Red over yellowExcellent post, of course. A small point, which I'm sure you're aware of: red over yellow merely means that the lever works both a stop signal and a distant signal (in the way that blue over black means the lever does both the points and the FPL). Typically an IB would have the home and distant worked by the same lever and typically a single lever working both home and distant would be used with IBs, but there are examples of IBs where the home and distant were separate. The (recently closed I believe) Elmton & Creswell Junction had a colour light IB with two independently worked mechanical distants unless I've misunderstood something. Similarly a combined home and repeater is a not rare economy these days. They had such a thing at Wem, as an example from off the top of my head. Usually how it works is you pull the combined home/repeater and the home stays red (and the repeater/distant stays yellow, obviously) until an approach track is occupied (possibly for a sufficient period of time) when the home goes to single yellow. If the starting signal is cleared in the meantime the home and its distant can instantly step up to green. Obviously the lever would be red over yellow in that case. kbarber in post 159371 said: Great efforts were made to avoid 'pull-throughs' (where a lever had to be pulled between two others that were already reversed).That's interesting, I've always called that a 'pull between', but obviously terminology varies on the railway! The GWR originally laid out its frames paying particular attention to avoid this, often slightly compromising on the logic of the levers. As I recall from the book I was reading, the GWR might want to avoid a situation like the following on a 4-track line: Main Distant: 1 Main Home: 2 Main Starting: 3 Relief Distant: 4 Relief Home: 5 Relief Starting: 6 You can see that if you have all of your signals off on the main and then pull off on the relief you're going to struggle to pull No.4 distant signal between levers 3 and 5. To avoid this the GWR would, I understand, originally have simply used lever No.4 for something else, some disc signal or other, let's say, and then make 5 the distant. In later years, instead of compromising on the logic, they compromised on absolute economy and left spaces. Nevertheless I can tell you from personal experience the one space they leave can still create a bit of an awkward pull at times and I have pulled 43 with 42 and 44 out of the frame more than once. Anothersignalman in post 159373 said: If that logic holds true, then the Peco box would have room for a maximum of 25 levers; and I'm not certain that's enough to work this sort of track layout, at least without considering mechanical selectors on the shunt signals. Was that a common practice in the UK?Mechanical selection was certainly done. Anothersignalman in post 159381 said: Off the top of my head, the local limit was about 400 yards for signal pulls, but less for points.The maximum distance a set of facing points can be from the lever is 300 yards these days unless I'm sorely mistaken. I believe that was extended from 180 yards? If memory serves? I'm not sure there's a hard and fast limit on signal pulls. Furness Vale has a mechanical distant that's 1 mile 966 yards out and I'm not sure that's the record even today. Anothersignalman in post 159381 said: bill_gensheet in post 159375 said:Quite but the siding leads onto a passenger line, even if it is not itself a passenger line.Any siding onto a passenger line had to be signalled and locked, but the extent of in-yard signalling varied. Returning to layouts and signalmen's step count for my money Crewe Junction has got to take the cake on that one, and it's single-manned, as opposed to its more famous big sister Severn Bridge Junction, which is double-manned during the day. It was a little while ago that I studied the layout in detail and if prompted I would probably select an example that's not as striking as some that I remember. Shrub Hill's also good for a workout, in that 44 needs 11, so your sequence is 48, 47, 45, 11, 44. In that order. You can of course pull 45 first, but then you'll need to fish 47 out from between 45 and 48 which is not as nice. Onto shed through the Middle Road is also a nice way to get caught out. You have two choices, either: 25, 30 back, 31, 51, 33, 52, 26 or 51, 30 back, 31, 25, 33, 52, 26. (You could pull 26 before 52, as long as you've got 33 off but because you have to wait for the barrow crossing to time out before you can pull 26 you're probably going to pull that last). But probably the best one that you'll do is start at the left-hand end of the frame because that's where the bell is. Send entering section. (You might think you can economise by doing this later, but you have to start with this because it's a very short section.) Walk down to the other end of the frame and put 78 back. Walk back and pull 27 and 20 reverse, walk back, pull 76 and then you should just have time to walk back to receive out of section. It's exercise, it's good for you. Makes you feel alive. Last edited: 09/12/2024 at 21:25 by TUT Reason: None given Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 10/12/2024 at 06:40 #159388 | |

|

Anothersignalman

107 posts |

TUT in post 159387 said:What a splendid discussion you've got going here, although I'm still a bit unsure whether you're going for an Australian layout, a Scottish layout, or are you just generally interested in either or both?I'm only familiar with Australian principles, but the structure we're working with is Scottish OO scale so I'm trying to translate what I know for that context. TUT in post 159387 said: I notice for example you use the term derails and the symbol does look more like that of a derailer. To me a derailer is a device that goes on a rail and, uh, derails a train. They are not really that common in the UK I would say, we would tend to use trap points (which the GWR tended to call 'catch points', although a common convention is that 'catch points' are the ones you use to catch runaways down a gradient and 'trap points' are for trapping trains in sidings, providing flank protection, etc.)Whatever works, really. I just had the symbols for derails available in my diagrams and drawing catch points takes a bit longer :P In practice the 'catch points' will most likely be static, represented by a spare point blade soldered to the outside of the running line, rather than anything functional. TUT in post 159387 said: Anothersignalman in post 159373 said:OK, so what was the upper limit? Here, we only ever used selectors between a maximum of two signals, almost always between two shunt signals with a small handful selecting between a home or a disc. Like the mid-route shunt discs, I think most of the selectors between home and shunt signals were gone by 1920.If that logic holds true, then the Peco box would have room for a maximum of 25 levers; and I'm not certain that's enough to work this sort of track layout, at least without considering mechanical selectors on the shunt signals. Was that a common practice in the UK?Mechanical selection was certainly done. Log in to reply |

| Model railway signal box interior advice 10/12/2024 at 09:13 #159389 | |

|

Ron_J

334 posts |

Perhaps I’ve missed it in the discussion but what sort of era are you modelling? If it’s after the mid 1960s it is very likely that your single line sections would have been converted to Scottish region tokenless block. This would mean a visually different type of block instrument - you can see a double ScR tokenless instrument in the photos of Dunkeld linked in other posts on this thread - and would usually require two levers to be used for Up and Down direction shunt keys. Although if space in the frame was tight, these were sometimes provided in slides on the block shelf adjacent to the instrument. Often when a box was converted to ScR tokenless a whole new frame was supplied from the regional S&T workshop at Irvine and these tended to have white traffolyte covers on the lever tops and catch handles, which are quite distinctive and would be visible on a model. As this is a crossing point on a single line, what do people who wish to get on or off at the station do if their train is the second to arrive when crossing another train? That seems an awful lot of infrastructure for 25 levers. I’m not saying it couldn’t be done but it seems very tight. You might want to have a look at the layout at Huntly, where a station crossing loop and large goods yard is controlled from a 25 lever frame. I see someone else has mentioned mechanical derailers versus trap points, so I won’t. Log in to reply |

| Model railway signal box interior advice 10/12/2024 at 11:45 #159391 | |

|

bill_gensheet

1427 posts |

Anothersignalman in post 159385 said:Anothersignalman in post 159385 said:

Random order of colouring in. I had not made any specific placement Anothersignalman in post 159385 said:

Yes, hand point on 3 & 4 as I was trying to minimise levers. Working the point adds 2 levers - assuming both lines are goods. Anothersignalman in post 159385 said:

OK, I can't count ! Distants could not be automated on a token system (but could be on the tokenless Ron notes) as 'distant(s) off' would be used to convey that the token was in the catcher for a collection at speed. Distant(s) on, stops off would mean a hand exchange. Depending on layout, for a pass both trains could need to be stopped outside the loop. Log in to reply The following user said thank you: Anothersignalman |

| Model railway signal box interior advice 10/12/2024 at 12:38 #159392 | |

|

kbarber

1746 posts |

clive in post 159379 said:kbarber in post 159371 said:Thanks Clive, I forgot that variant (even though I worked one like that at Kensington South Main). I think it was a more recent way of doing it, hence its relative rarity,I read somewhere that there's an alternative - less common but still found - where the signal levers are all put in the middle and the points etc. at the ends. If most moves are just straight through or just one or two lever pulls, there's much less walking around required. Also worth saying (although completely irrelevant to Anothersignalman's query) that where a box was double- (or more-) manned, each part of the frame would most likely be laid out in accordance with whatever principle had been adopted, even though the levers were mechanically and visually in a single frame with no obvious division. Even more irrelevant to the query, but of interest, were the double-framed boxes sometimes used by the Midland Railway. St Pancras Station was probably the best known, a double-width box with the frames down the middle so the 2 signalmen worked facing each other. At Bedford Junction the frames were on both sides of a double-width box and the signalman worked between them; one frame worked the avoiding line and the other the original line through the station, with (I believe) just one connection between them. There was also Mill Hill, where there was a double-length box with one frame on the slow lines side at one end and t'other on the fast lines side at the other. The only physical connection between the two sets of lines was the middle siding; the lever for the crossover trailing from the up fast also operated a bolt lock on the slip crossover trailing out of the slow-to-slow trailing crossover and that was the only connection between the two sides of the box. Log in to reply The following users said thank you: Anothersignalman, TUT |

| Model railway signal box interior advice 10/12/2024 at 14:32 #159393 | |

|

clive

2793 posts |

Then allow me to offer a previous version of Liverpool Street, with two boxes (one with four 60-lever frames with the signallers between them and the other with a 136-lever straight frame), plus 7 ground frames (2x8-lever, 4x6-lever, one 2-lever). https://www.davros.org/rail/diagrams/old_liverpool_street.extract.gif Log in to reply The following user said thank you: Anothersignalman |